Services > Chemical Cleaning & FINFOAM® > FINFOAM

The FINFOAM® Process

Dirty fin fan coils reduce the cooling efficiency of heat exchangers. FINFOAM®’s low pressure, high volume cleaning process removes dirt and debris safely and thoroughly. Cooling equipment begins performing at an optimal level and the results bring multiple financial benefits. Clean exchangers result in less energy requirements allowing fans to be turned off or run more slowly. Equipment life is extended and most importantly, production can be increased where cooling has been detrimental to output.

FINFOAM® cleans blocked heat exchanger fins. Dirty fins restrict air-flow through the exchanger unit causing a significant drop in cooling efficiency and a loss in production. An environmentally friendly foam cleaner and low pressure rinse remove dirt, oil and debris from the entire heat exchanger unit. FINFOAM®’s process has been tested and proven in industrial facilities throughout the world.

A cleaning process that is eco-friendly, safe, rapid and thorough.

Our technicians use an environmentally friendly chemical foam that saturates and expands into every crevice of the heat exchanger. A low pressure rinse minimizes overspray and is safer for both personnel and the equipment. The traditional cleaning method (hydroblasting) damages delicate fins and compacts the debris into the center of the tube stack. Our process completely removes dirt, debris and corrosive elements without damaging equipment. FINFOAM® has been tested and proven in industrial facilities throughout the world.

Meeting Your Plant-Specific Needs

Your facility may pose a special challenge or have specific needs. Whether it is an oil refinery requiring a specially blended cleaning formula or a remote destination with difficult access, FINFOAM® has been tested and proven in all types of operating conditions.

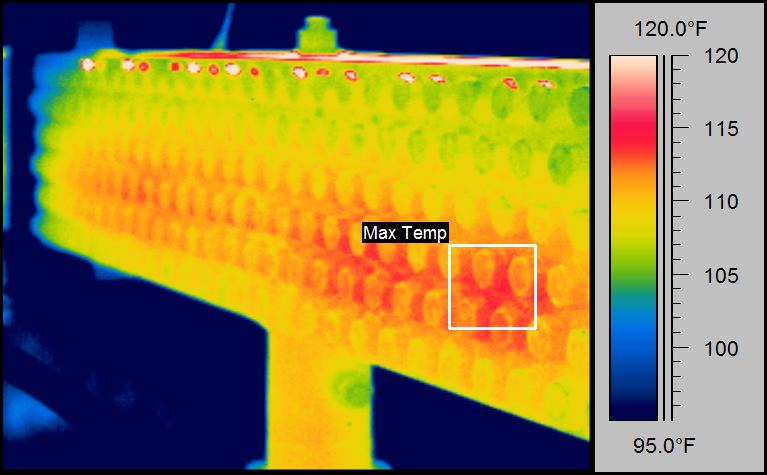

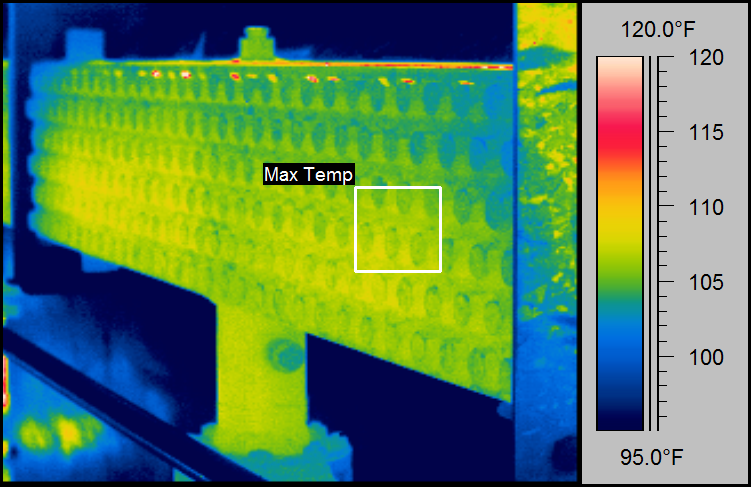

Before FINFOAM, just hydroblasted by another company: 115 Degreees F

After FINFOAM cleaning in just 1 hour: 104 Degrees F

Return equipment to peak performance and improve energy efficiency.

Benefits |

Improved heat transfer cooling performance and unit efficiency Increased production (throughput) Decreased amps to run fan “hard” reduces operating costs (and in itself can pay for the entire cleaning project) |

Prolonged unit life by removing corrosive deposits Reduced maintenance cost Zero damage to fins |

Applications |

Petrochemical Refining Gas Transmission Gas Plants Pulp |

Paper Manufacturing Mining Mineral Processing Power Facilities |

Prolonged unit life by removing corrosive deposits.

CASE STUDY – Coker Unit

Eight exchangers with 2 fans each were severely plugged with coke fines and limiting the entire refinery in the southeast. Taking about 1 1/2 hrs. per fan, FINFOAM® finished the job in 2 days and gave operations an additional 25 degrees on their outlet. Previous cleaning attempts by other companies had routinely taken a week and improvements were minimal.

Annual Cost Savings: >$800,000

CASE STUDY – Alky Unit

FINFOAM® was contracted to clean a major refiner’s Alky unit, after poor results from previous attempts by competitors. With over 100 fans in the unit the job took just 12 days.

Average results showed a 35-degree increase in delta T and the payback was noticed before the job was even completed. Increased production paid for the overall job in a few weeks.