Services > Hydroblast, Vacuum & Big Pump > Hydroblasting

Cleaning Processes

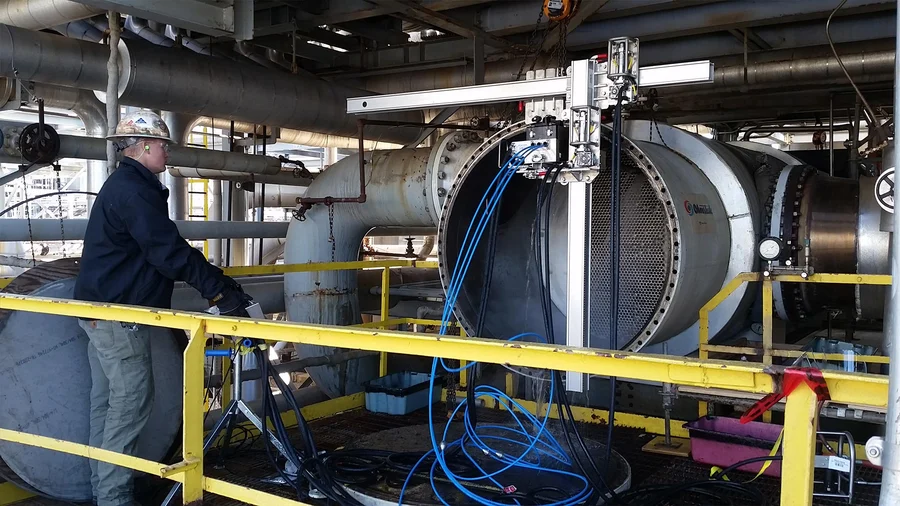

Our water blasting cleaning technology removes unwanted fouling deposits that impair process equipment and production efficiency. With our experience, customized equipment, and safety record in this field, we offer the broadest line of cleaning processes and unique solutions.

Custom Designed Equipment

Capable of cleaning applications where pressures of 10,000 to 40,000 psi are required, our fleet and our personnel can get your operating equipment back to full production and efficiency as quickly as possible. Our custom-designed nozzles and tools combined with our diesel powered pumps enable us to provide unmatched speed, effectiveness, and safety.

Our team can get your operating equipment back to full production efficiency quickly.

Benefits |

Fast, efficient cleaning methods Unique customizable solutions Capabilities of 10-40K psi Custom-designed nozzles & tools Safe, automated capabilities |

Applications |

Boilers – recovery, power, utility Boiler Tube Cleaning Process Pipes and Equipment Digesters Tanks Surface Cleaning – Interior and Exterior |

Drainage Lines Railcars, Barges, and Ships Reactors, Tanks and Vessels Heat Exchangers and Evaporators (multi-tube lance cleaning) Hydro-demolition |

Problem

A customer had a vital system process line with a single entry point. Most of the piping was buried in reinforced concrete and not readily accessible without costly excavation or modification. The line required cleaning, and all waste material had to be removed and verified while the cleaning work was performed.

Solution

We designed, fabricated and tested the tooling and equipment to clean and remove all bio-fouling, waste material, and debris. The customer observed and verified our proprietary cleaning process via video inspection and documentation.