Services > Hydroblast, Vacuum & Big Pump > Boiler Tube Cleaning

Safe Efficient Boiler Tube Cleaning

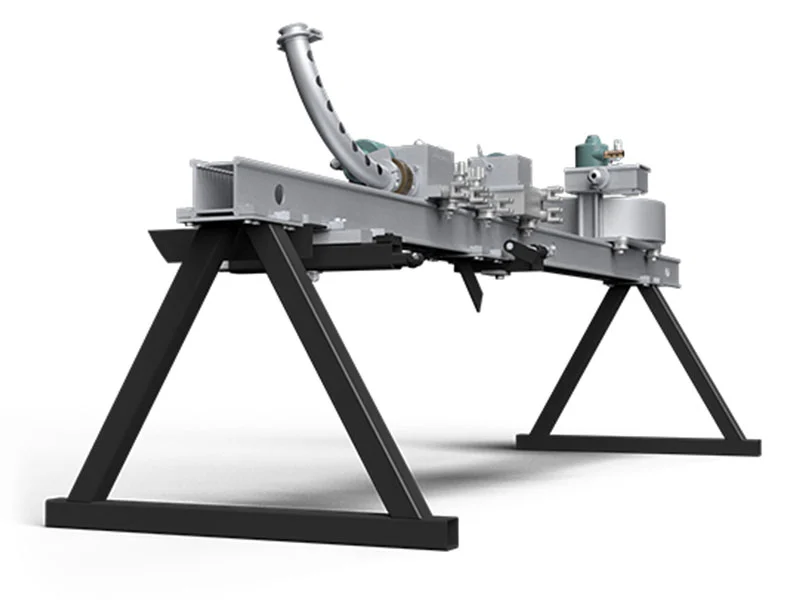

Thompson’s automated boiler tube cleaning with the help of the boiler chemical cleaning process is the ideal way to mechanically clean the interior tube surfaces of package and other boiler designs. This boiler chemical cleaning is a fully customizable system fit to your particular boiler that is inserted through the mudrum manway and removes any need for an operator to enter the vessel.

This boiler tube cleaning technology also includes a camera system used for better tube indexing, hose containment and more. It can deliver up to 50 lbs. of push-force to clear plugged tubes, and easily travels through long lengths and bends cleaning in both directions under full pressure ensuring a safe, precise and thorough cleaning every time.

Water & impact resistant camera system

Benefits |

Decreased Hazard Exposure No confined space entry required Precise tube indexing Highly efficient cleaning capabilities Water impact resistant camera system

|

|

Applications |

Boiler Tube Bundles Additional Automated Hydroblasting Capabilities |

Problem

Rust scale buildup on 119 boiler tubes required cleaning and passivation before being shipped to a major power plant.

Solution

The Thompson automation team thoroughly and safely cleaned all tubes with automated boiler tube cleaning.