The Benefits and Risks of Dry Ice Blasting

BLOG

DRY ICE BLASTING

Here at Thompson Industrial Services, we make it a priority to push research forward on cleaning solutions that are safe for the environment. This does include the “environment” in the larger sense, that is, the ecosystem consisting of the atmosphere, waterways, and soil, but it also includes the immediate environment.

When we are conducting routine maintenance or addressing an emergency at a client’s plant, we prefer to use a solution that does not present a threat to the plant’s equipment or employees. Sometimes, it is necessary to use a chemical cleaning solution, and in those cases, we adhere to strict safety standards to make sure that the activity is contained and the surrounding workers and equipment are protected.

But when a non-toxic, zero residue cleaning process is available and just as effective, we always opt for it. Dry ice cleaning is one of those processes.

“Explosions” in the Plants

Believe it or not, when one of our technicians cleans a surface with our dry ice cleaning process, he is triggering hundreds of thousands of gaseous “explosions”—right inside your plant! Before you picture your facility going up in a mushroom cloud, however, let us explain that these are usually referred to as “micro-explosions,” or more technically, “sublimation” when converting from a solid to a gas.

Each one is the result of a small pellet of frozen carbon dioxide at minus 109 degrees F rapidly turning into a gas at atmospheric temperature. Because the gas form of CO2 expands to take up so much more space than the solid form, this rapid phase change has a devastating removal effect on the residue in its immediate vicinity, i.e., the debris built up on the surface being cleaned.

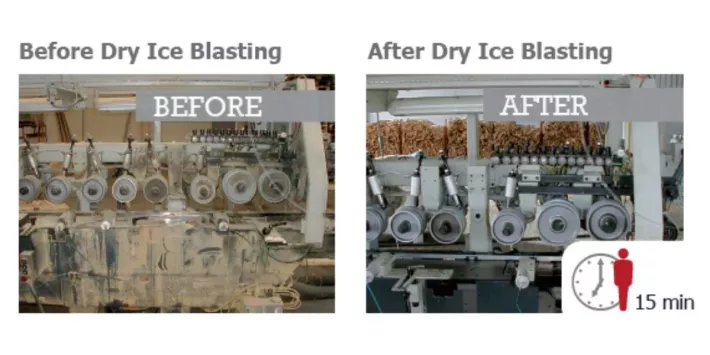

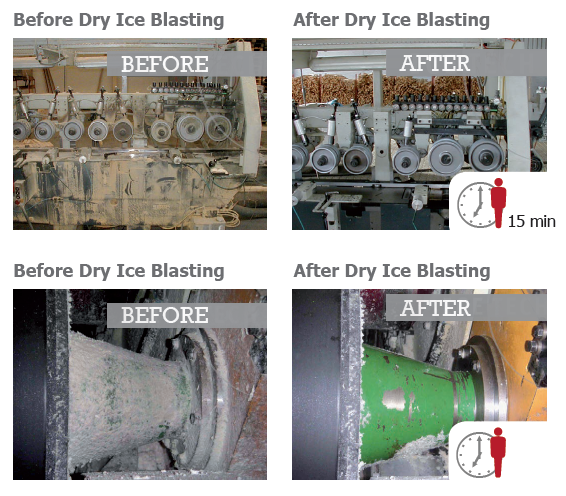

These micro-explosions are very effective at stripping away debris, but not aggressive or strong enough to negatively affect the surface itself. This makes dry ice cleaning an extremely desirable option, especially when compared with competing services. Sandblasting, for instance, can easily damage underlying surfaces.

Where Does it Go?

Surface cleaning with dry ice isn’t just safer than chemical cleaning and sandblasting—it’s also quicker, due in large part to its lack of residue. After each micro-explosion, the resulting CO2 gas dissipates into the immediate atmosphere, creating no solid or liquid waste residue.

The only debris left on the floor after the cleaning is the substance that was removed from the now-clean surfaces, and almost always in a “dust” form. This is easily swept or vacuumed up and disposed of, drastically shortening the overall time needed for the cleaning project and therefore the budget required for it.

Although the CO2 does not create a solid or liquid residue, it does have a short-term effect on the immediate environment when in a confined space or stagnant area, which technicians must understand and address in order to conduct a dry ice cleaning job safely.

Dry Ice Cleaning Risks to be Mitigated

There are two primary risks that dry ice cleaning technicians must protect against: burns and suffocation.

Dry Ice Burns

Dry ice is frozen carbon dioxide. Carbon dioxide becomes a solid at about -109°F, so it must be stored at or below that temperature in insulated containers to remain frozen. If dry ice comes in contact with human skin, it causes instant frostbite and potentially permanent damage. Gloves, protective clothing, and goggles are absolutely essential when handling a substance at this extreme temperature.

Suffocation

Once the CO2 has become a gas, it temporarily takes up a great deal of space in the immediately surrounding atmosphere and thus can displace oxygen under certain conditions. This is especially true if the work site is in an enclosed, poorly ventilated area. Humans cannot breathe carbon dioxide, and the sudden expansion of CO2 displaces the oxygen naturally occurring in the atmosphere.

Unless a technician is protected with extra ventilation or personal oxygen equipment when exposed to these conditions (i.e. confined space or inadequate ventilation), he is in danger of suffocating due to the reduced oxygen levels unless an auxiliary supplied-air system is utilized.

Trust the Dry Ice Cleaning Experts

Like any powerful tool, dry ice cleaning comes with both great benefits and serious risks. At Thompson Industrial Services, we approach this application with the same high level of safety training as all of our services. Whether our teams are handling powerful hydroblasting equipment, toxic chemicals, or frozen CO2, they are fully trained to do so safely.

Our clients routinely provide positive feedback expressing their surprise at the level of knowledge and safety-consciousness that our teams display, from the project manager to every member of the crew.

Get in touch with us today to find out more about this time-saving, money-saving, and incredibly effective cleaning method.

Related Articles

Thompson Industrial: Your Chemical Cleaning Expert - When you need industrial cleaning services, there is no better option than Thompson Industrial Services.