Dry Ice Blasting: A Unique Solution

BLOG

There are certain cleaning tasks that plant maintenance personnel dreads tackling. An example situation is when residue builds up on equipment and must be removed for work to continue. This can be challenging when exposure of the surrounding equipment makes it impossible to use standard cleaning techniques. Sandblasting might damage sensitive surfaces or enter rotating equipment, and water would be disastrous to electrical components. Dry ice (AKA “cryogenic”) blasting is an advanced and often quite viable cleaning approach that gets the job done without any supplemental waste while protecting the equipment and underlying surfaces.

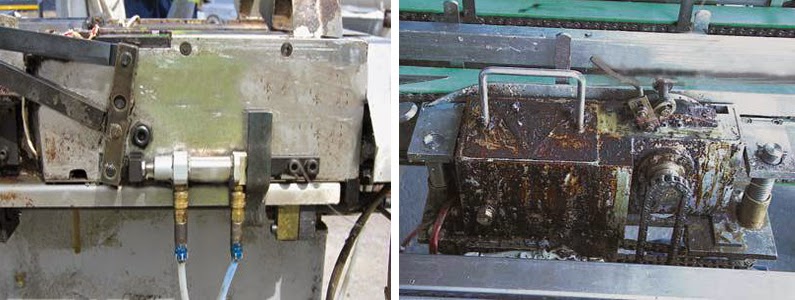

A Sticky SituationIt’s hard to imagine a tougher cleanup job than glue residue. When the manager of a board mill contacted us for help, we quickly saw why he was out of ideas for solving his problem. A hood was caked with glue vapor, but the electrical and hydraulic equipment located nearby made it impossible to safely use water or sand blasting. The job called for something more specialized—something that could quickly and thoroughly remove the glue vapor buildup without introducing harmful particles or moisture into adjacent equipment or the environment.Carbon Dioxide to the RescueFortunately, at Thompson Industrial Services we had just the solution for this sticky problem: dry ice blasting. As you may know have used personally for shipping, dry ice is carbon dioxide (CO2) in frozen form, which for our application is with micro sized pellets. When applied to the hood surface in a pressurized air stream, it froze the glue residue, making it brittle and breaking it loose without harming the surface underneath. Because the dry ice evaporates virtually instantly, it does not create moisture or any residual waste whatsoever that could damage electrical parts. We fit the cleaning job into the board mill’s maintenance schedule (although quite frequently it can be utilized while process and electrical equipment remains on line), and they were so pleased with the results that they decided to make the cleaning a regular occurrence.Creative Cleaning PracticesCan dry ice blasting solve a difficult cleaning situation for your plant? If you are facing a piece of equipment that desperately needs cleaning but you can’t figure out how to do it safely, contact us to have us take a look. You’ll be amazed at the speed and effectiveness of this and many other of our alternative creative techniques and solutions.