The Future of Hydroblast Industrial Cleaning is Now - in Automation!

BLOG

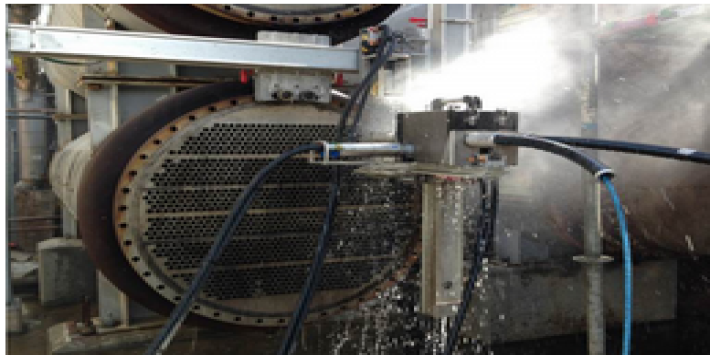

High pressure waterblast cleaning is a very effective and versatile solution for many of the extremely challenging deposit cleaning problems that our teams are tasked with to resolve. Besides—and most importantly—exposing our crew members to high pressure water of up to 40,000 PSI, the jobs often require repetitive actions, frequently in hazardous “back splash” conditions. For these reasons and numerous others, including productivity and cost effectiveness, our company has invested heavily in automating the cleaning process. With this state-of-the-art technology, combined with talented and dedicated personnel, our customers are experiencing very exciting results in the field of automated hydroblasting!

A Safer Form of High Pressure Waterblast Cleaning

In one sense, the simplest way to keep industrial cleaning personnel safe during a job is to remove them physically from the area of danger. Of course, that means developing a way to do the job remotely, and that’s where our 19 years of automation research and development come in. In one recent success story, a three-man team did what previously required four, in half the time, while staying completely out of harm’s way. The key was a triple-lance,automated unit that the team operated from a safe distance.

Safety, Savings, Increased Productivity and Cleaning Effectiveness

Removing our technicians from the immediate vicinity of the equipment also saves a lot of time and money during hydroblasting operations. It’s literally a win-win situation: our company takes a huge step forward in Thompson’s commitment to keeping our workers safe, and our clients enjoy the benefits of faster, less costly maintenance calls. In addition, since with automation we clean under full pressure during both the ‘in’ and exit strokes, literally 100% more cleaning dwell time is realized, resulting in cleaner equipment in up to half or (more routinely) even less than half the time than conventional manual methods.

Constantly Moving Forward

The efficient, fully automated hydroblasting process described above is just one facet of our development in this area. Remote shotgunning and rotary jetting tools are a couple of the other groundbreaking technologies we are constantly making even more strides within our double pursuit of safety and efficiency. Even complex jobs like steel and concrete hydro-cutting are within the capabilities of our automated hydroblasting, which incorporates ultra-high pressure (40k) applications.

Automated heat exchanger cleaning utilizing multiple lances

Press Contact

- Emily Martin

- Marketing Manager

- 100 N. Main Street

- Sumter, SC 29150

- (803) 773-8005

- emartin@thompsonind.com