Taking Boiler Tube Cleaning into the Future

BLOG

At Thompson Industrial Services, our innovation in automated cleaning solutions has transformed many of our processes, whether they involve hydroblasting, chemical cleaning, or spraying a specialized product like FINFOAM. In each application, replacing a hands-on approach with remotely controlled robotic tooling has helped us make important progress in safety, speed, accuracy, and power. Boiler tube cleaning provides what may be the clearest example of just how much progress is possible when we make the best use of automated technology. If this is a maintenance topic that has always been a “thorn in the side” of your facility, keep reading—Thompson Industrial Services can help!

Automated boiler tube cleaning transforms this core maintenance task.

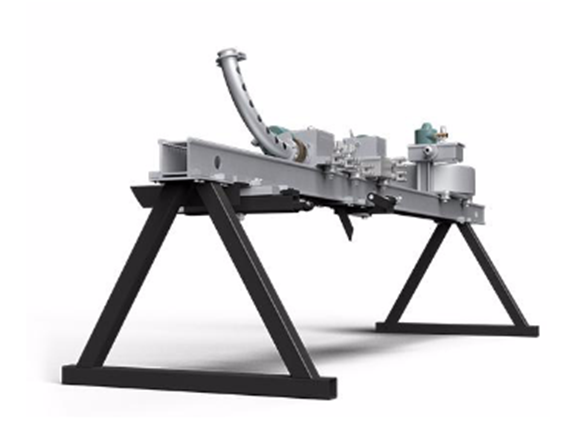

Automated Boiler Tube Cleaning EquipmentThe equipment we use for automated boiler tube cleaning is compact—it’s small enough to be inserted through the mud drum manway, gaining access to boiler tubes very quickly as it is manipulated remotely by one of our expert, highly trained technicians. Once the unit is in place, a camera system allows the technician to clearly see what the cleaning needs are, track progress, and document the results once the cleaning job is complete.The automated tooling is expertly designed to clean boiler tubes completely, safely, and quickly, delivering up to 50 pounds of push force to clear plugging. One important factor in the speed of this cleaning approach is the fact that the tooling cleans in both directions as it is manipulated—essentially performing twice as much work as a human technician would be able to perform through a hands-on cleaning approach.Customized for Your EquipmentEach boiler tube cleaning job is unique, and we customize our flexible automated equipment in order to bring the highest possible level of service to each of those jobs. This is an incredible efficiency benefit for each of our clients; the more closely the solution is customized for a piece of equipment, the more thoroughly the unit will be cleaned and the more effective it will be when it is back online.Our teams use a detailed, careful project planning approach before beginning any job. No matter how “routine” a cleaning job may seem, a creative solution may be able to remove tough, years-old deposits that previous cleanings were not able to touch. It may also cut downtime by hours or even days, thanks to increased cleaning power and the ability to keep human workers out of harm’s way throughout the job. This commitment to look at each project through the lens of innovation and to never be content with the way things have always been done is part of the integrity that our clients value in our industrial cleaning teams.Boiler Tube Cleaning ExpertiseThis state-of-the-art automated boiler tube cleaning equipment is powered by decades of experience. Our technicians understand the capabilities of the tools they use to clean boiler tubes and other industrial equipment, and they carefully determine the safest, most effective solutions for each cleaning project. If a client’s proposed boiler tube cleaning method—or the one that other service providers have used in the past—does not appear to be the optimal one, our team will propose an alternative that may preserve the client’s equipment and lead to better results for the long term.Waste containment during any boiler tube cleaning job is an aspect that our technicians take very seriously as well. The debris and chemicals removed from equipment are often hazardous to the environment and to human workers, and we use advanced equipment and methods to safely dispose of them. In some cases, the client’s facility policies even require that we collect all debris, fluids, and chemicals produced during a cleaning job and transport them off site without allowing any to escape. Our experience and advanced equipment, including vacuum technology and high-capacity units, allow us to meet these expectations while still minimizing downtime for the client’s process lines.

Automated boiler tube cleaning may be an incredibly valuable service for your facility, and our teams are uniquely qualified to perform it safely and quickly. We encourage you to contact us and tell us about your cleaning needs, as well as safe excavation, combustible dust removal, wet and dry waste vacuuming, and other complex industrial cleaning services.

Press Contact

- Emily Martin

- Marketing Manager

- 100 N. Main Street

- Sumter, SC 29150

- (803) 773-8005

- emartin@thompsonind.com