Safety Comes First: Cleaning Heat Exchanger and Other Equipment

BLOG

One of the priorities that has remained constant throughout the decades for us here at Thompson Industrial Services is safety. Whether we’re cleaning heat exchanger components, dry ice blasting, or digging with our pneumatic vacuum excavation equipment, we are always committed to keeping our operations and the surrounding area safe. Many times, OSHA inspectors find that we’re not only meeting their requirements, but that our internal safety policies actually exceed those requirements! Our teams recently worked with a client that had a very good reason to place safety at the top of their priority list. Here’s how we helped them get the job done while keeping every employee safe from harm. Accidents Can Happen In our industry, we have always had to grapple with the idea of “human error.” Many of our safety policies are designed to minimize the opportunity for a human technician to make a mistake that could damage property or hurt someone else while they are cleaning heat exchanger equipment with a hydroblaster or performing some other task. The client in this particular case initially contacted us because they were specifically looking for an industrial services provider that could provide 100% automated hydroblasting at their chemical plant. Sadly, there had been a past incident at the plant in which an employee was injured in a hydroblasting accident. The plant understood that automated solutions could prevent many of those sorts of accidents, and they contacted a number of different providers to find out what they could do for them in terms of automation. Thompson’s Audition When we got the request, we were excited to show the client what our advanced automated solutions were capable of in terms of cleaning heat exchanger and other industrial equipment. We assembled a wide range of tools, including 3d and 2d tools for tank cleaning, automated shotgun equipment, and much more. At the site, we unloaded the trailer and spent a “trial week” working at the facility, showing the client how powerful, accurate, and most importantly, safe our hydroblasting equipment is when combined with remotely controlled positioning systems.

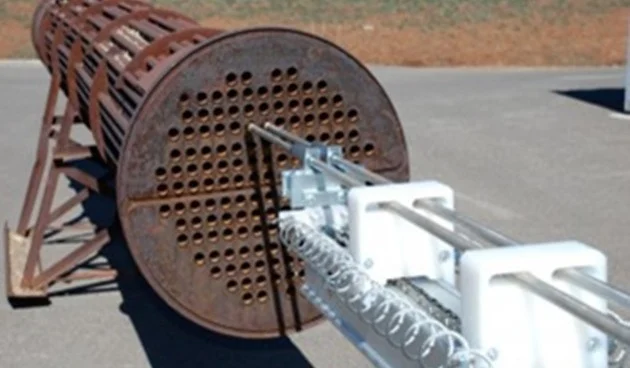

Our automated rigid lancing system at work

It’s always a great thing when we are able to do something truly remarkable for a client near the beginning of our working relationship, and that was certainly the case with our trial week with this client. The first line we tackled with our cleaning equipment was one that had never been thoroughly cleaned; in the past experts had told them that due to the nature of the line, it would never be possible to clean it to the level that they would like. But it didn’t take us long to set up our remotely controlled system, remove the debris from the interior of the line, and show the client that the line was now completely clean for the first time since it was installed. A Week Becomes a Month It turned out that the trial week was not enough time for our client—they wanted more of what Thompson Industrial Services could provide to clean the equipment at their chemical plant! That week stretched out into a month, and our teams worked on a wide range of equipment on the site with the same success as that initial line cleaning. Some of the equipment we’ve safely and completely cleaned there includes one-inch to six-inch lines, cyclones, tanks, and multiple drain lines. At a chemical plant, those units provide some very tough challenges in terms of types of debris and scale buildup, but our team completely satisfied the client with their speed, thoroughness, integrity, and of course, their constant attention to safety. Overall, the client was relieved and very impressed with the level of our team’s service, and we plan to return and provide more assistance at the site as needed. Your Source for Hydroblasting and Chemical Cleaning For heat exchangers, large vessels, piping, boilers, and other industrial equipment, our automated hydroblasting services make it possible to achieve cleaning with both thoroughness and safety. There’s a reason our motto is “Be safe, be good, be great,” with “Be safe” at the very beginning. The protection of your employees and our own is our first priority, and we hope you will give us the chance to prove it to you!

Back

Press Contact

- Emily Martin

- Marketing Manager

- 100 N. Main Street

- Sumter, SC 29150

- (803) 773-8005

- emartin@thompsonind.com