Automated Hydroblast Technology Gets More Sophisticated

BLOG

The continual improvements that the research teams at Thompson Industrial Services make to our automated hydroblast systems carry huge benefits for our clients. True, it’s a lot of pressure for our researchers to keep pushing the boundaries of a technique that is already at the cutting edge in our field, but if anyone is up to the task, they are. Today, we tell you about the most recent technology update to our automated service, which gives our experienced hydroblasting technicians more control, speed, and efficiency in boiler tube cleaning than ever before.

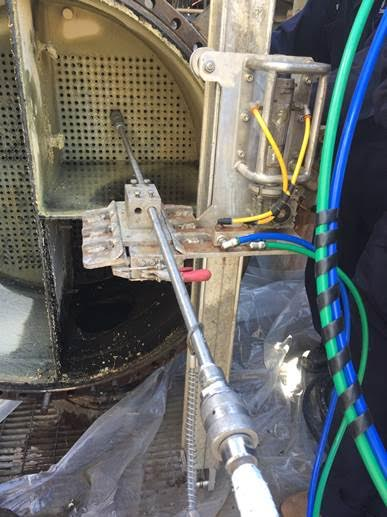

Our automated heat exchanger cleaning equipment in action

Some Key NumbersWe know that numbers always tend to attract attention, so we’ll start off our discussion with some powerful statistics from a recent job that our hydroblast technicians handled for a client. The job was jetting tubes for two heat exchangers at a major refinery, a job that took another industrial cleaning service slightly more than 100 hours total just about a year ago. Using the new advancement we are talking about today, our hydroblasting equipment accomplished the entire job in less than 24 hours. That’s over 75 hours of downtime cut, for a value of about $13,000 for the client.Between the two heat exchangers, there were a total of 1,156 tubes that needed to be cleaned. The key benefit of our improved hydroblasting service was the ability to move very quickly from one of those tubes to another, cutting downtime and providing our client with those very welcome financial savings.Smart Indexing SystemThe basis of our hydroblast service for this job was our triple lance automation system, which accomplishes the cleaning far more quickly, safely, and precisely than water blasting by hand. The new Smart Indexing System, an addition to our remotely controlled equipment, makes it possible for our technicians to manipulate the equipment using a tablet via bluetooth. It also increases the positioner’s speed in moving the hydroblasting tip from one hole to the next, without losing any accuracy or power.In a further effort to remove human error from the equation, the Smart Indexing System notifies the technician if he moves the hydroblasting tool to a boiler tube that has already been cleaned. This is a helpful, potentially time-saving feature during a cleaning that involves over 1,000 tubes! This smart indexing system is calibrated to fit your particular exchanger. In addition, we offer capabilities for heat exchangers and domed evaporators with confined spaces. Every automation job is customized to your facility’s specific needs.Superior Boiler Tube/Heat Exchanger Cleaning ServicesThompson Industrial Services has spent decades providing superior cleaning services for heat exchangers and boilers throughout the southeastern and central United States. Continual advances in technology, including the incorporation of the Smart Indexing System, are a large part of the reason that our clients in the Southeast and throughout the United States trust us with their equipment: they know that we are doing everything possible to save them time and money with each cleaning job while keeping operators safe. Clients like the one we told you about at the beginning of this article, that previously worked with other industrial cleaning providers for their maintenance needs, immediately recognize the difference in Thompson Industrial Services’ commitment to safety and quality. That’s hard to argue with when a boiler tube cleaning cuts over 75 hours of downtime from the job!Other Hydroblast ApplicationsThe automated positioning systems that we use to hydroblast boiler and exchanger tubes are also integral parts of our other hydroblasting services. When cutting through reactor heads or steel walls, for instance, the precision of this equipment makes it possible for our technicians to quickly execute perfectly round, perfectly sized cuts with beveled edges for easy rewelding. Each project that incorporates our robotic equipment gets a fully customized approach, with the emphasis on planning and understanding the equipment, requirements, and challenges that is a long tradition at Thompson Industrial Services.If your manufacturing facility, refinery, or plant requires heat exchanger or other major equipment cleaning, we want to make your project our next impressive success story! If maintenance on your equipment is long overdue because of restricted access or a setting that is hazardous for human technicians, it’s even more important that you contact us to learn more about our automated hydroblast solutions; they are versatile enough to fit into virtually any application and perform a complete, fast cleaning. We will be glad to talk with you soon!

Back

Press Contact

- Emily Martin

- Marketing Manager

- 100 N. Main Street

- Sumter, SC 29150

- (803) 773-8005

- emartin@thompsonind.com