Services > Lifecycle Service Solutions > Pre-Commissioning Cleaning

Efficient, Custom-Engineered Pre-Commissioning Cleaning Services

Our team seamlessly partners with you to stay on-time and on-budget with extensive engineering and pre-planning, frequently by incorporating more efficient or cost-effective alternatives to conventional means. We offer complete turn-key or itemized services listed in our capabilities below.

We Understand the Importance

Although plants are erected utilizing all new equipment and materials, the components typically contain foreign deposits such as milling oil, rust, construction debris, weld splatter, dirt or even sub-surface contamination like chlorides or fluorides that can directly affect metallurgy and alloys during operating or under stress conditions.

Investing potentially tens of millions to billions of dollars to plan and erect new equipment or entire plants can be at risk near- and even long-term unless crucial pre-operational cleaning of select components are thoroughly and effectively cleaned to exacting standards.

In addition, minute microscopic-sized particles to <1 micron can detrimentally impact or even repeatedly shut down lubrication and hydraulic systems or cause catastrophic erosion damage to down-stream equipment such as turbine blades and rotors.

Also, a consideration for pre-commissioning is conditioning the metal and alloy surfaces that my need to be effectively “pickled” and/or passivated, and then preserved and protected for erection weeks or even months later.

Pre-planning + EngineeringLube Oil FlushingPre-operational Chemical CleaningSteam BlowsHydrostatic TestingDrone Inspections |

Hydrolization with AutomationUHP HydroblastingCustom Engineered SolutionsSponge BlastingDry Ice BlastingPigging + Brushing |

Chemical cleaning with multitudes of methodologies, techniques and chemistries

Applications |

Exchangers, process lines, tanks Fin fan units Pre-commissioning systems Pickling & passivation Cooling water systems Process piping |

Oil coolers & condensers Resin beds Scrubbers Boilers: utility & industrial Utility piping Pickle line equipment |

Expertise, Precision Execution and Talented Personnel

Lube Oil Flushing

We deliver custom-designed chemical cleaning and oil flush procedures complete with system flow diagrams with engineered circuits and flow velocity requirements to achieve crucial specifications. The following variables are evaluated for each specific application:

- Metallurgy / alloy vs. chemical compatibility critique

- Post-cleaning needs (e.g. drying) & system reassembly guidance

- Site specific health, safety and environmental standards

- Turnkey needs from flush oil to factory fill lubricants

- Single stage or multi-stage solvent systems with or without heat

- Degreasing, mill scale removal and passivation steps

- Custom-designed filtered oil flushing stage

- Continuous – full flow filtration during all stages to design specs i.e. ISO 16/14/11 (NAS 5)

We ensure highly trained personnel and clear communication

Steam Blows

After a complete chemical cleaning of piping, and hydraulic testing of lines, we ensure all system parts are prepared for steam blowing and 100% safety measures are taken. We ensure highly trained personnel, clear communication with your plant personnel, pre-evaluation of all hazards and all precautions put in place. With every job you will receive:

- Steam Blow Hydraulic Engineering Design

- Steam Blow Temporary Piping Design

- Optional Steam Blow Temporary Piping Support Design & Pipe Stress Analysis

- Steam Blow Work Instruction Package

- Steam Blow Final Report

Our trained team will meet your exact specifications

Hydrostatic Testing

Thompson’s pre-commissioning services are completely turn-key. As a part of these services, we’ll perform a complete and thorough pressure check of your piping, vessels and associated equipment. Our trained team will meet your exact specifications for pressure levels and the amount of time to hold pressure.

BENEFITS TO THOMPSON’S METHOD

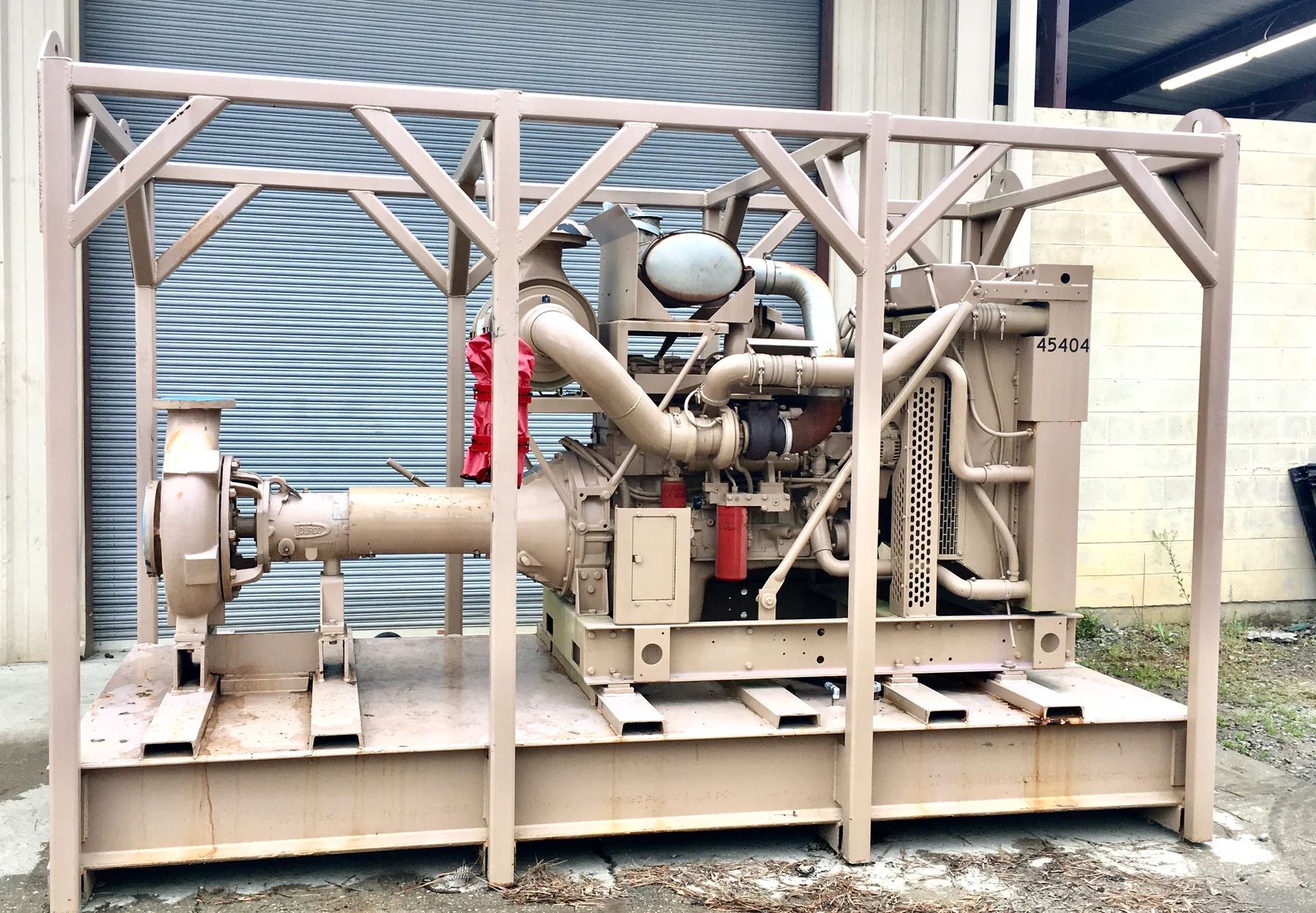

While our clients may choose either high-volume or standard 10K, we have seen major success with our custom high-volume pumps which have the ability to fill the boiler much faster than the traditional method.

- High energy pumps to 2,250 HP

- 1,200 GPM and 10K PSI

Our trained team will meet your exact specifications

Pigging + Brushing

Thompson provides safe, efficient pipeline pigging and brushing services by our team of highly skilled, experienced personnel. We have the equipment and turnkey service offerings to tackle any pipeline pigging need from single projects to pre-commissioning and inspection testing to on-going maintenance. We have unique solutions to customize even the most challenging pipeline sizes and configurations.